Category: Drying equipment

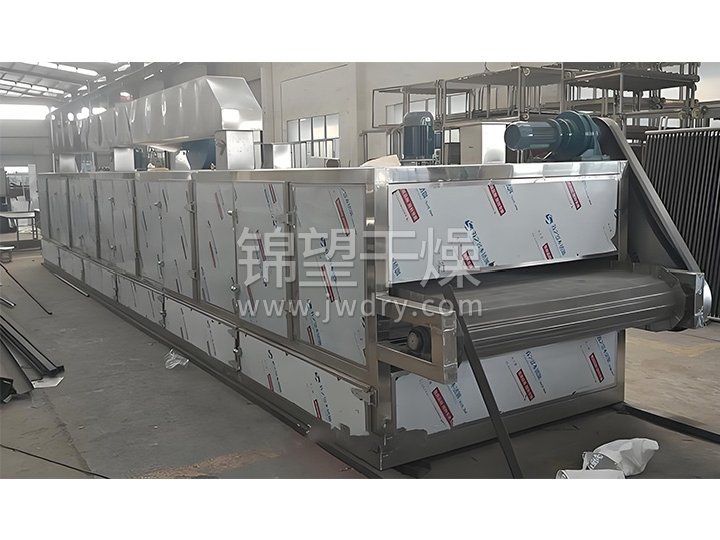

Introduction: Product IntroductionThis machine is a continuous flow drying equipment used for drying sheet, strip, and granular materials with good breathability. It is particularly suitable for materials with high moisture content, such as dehydrated vegetables an…

This machine is a continuous flow drying equipment used for drying sheet, strip, and granular materials with good breathability. It is particularly suitable for materials with high moisture content, such as dehydrated vegetables and traditional Chinese medicine slices, but not allowed to have high temperatures; This series of dryers has the advantages of fast drying speed, high evaporation intensity, and good product quality. For dehydrated filter cake like paste materials, they can also be dried after granulation or rod-shaped production.

| model | DW-1.2-8 | DW-1.2-10 | DW-1.6-8 | DW-1.6-10 | DW-2-8 | DW-2-10 | DW-2-20 | |

| Number of units | 4 | 5 | 4 | 5 | 4 | 5 | 10 | |

| Bandwidth (m) | 1.2 | 1.6 | 2 | |||||

| Drying section length (m) | 8 | 10 | 8 | 10 | 8 | 10 | 20 | |

| Paving thickness (mm) | 10-80 | |||||||

| Operating temperature (℃) | 50-140 | |||||||

| Steam pressure (Mpa) | 0.2-0.8 | |||||||

| Steam consumption (kg/h) | 120-300 | 150-375 | 150-400 | 180-500 | 180-500 | 225-600 | 450-1200 | |

| Drying time (h) | 0.2-1.2 | 1.25-1.5 | 0.2-1.2 | 0.25-1.5 | 0.2-1.2 | 0.25-1.5 | 0.5-3 | |

| Drying strength kg water/h | 60-160 | 80-200 | 85-220 | 100-260 | 100-260 | 120-300 | 240-600 | |

| Total power of equipment (kW) | 11.4 | 13.6 | 14.6 | 18.7 | 19.7 | 24.5 | 51 | |

| long(m) | 9.56 | 11.56 | 9.56 | 11.56 | 9.56 | 11.56 | 21.56 | |

| Overall dimensions | wide(m) | 1.49 | 1.49 | 1.9 | 1.9 | 2.32 | 2.32 | 2.32 |

| height(m) | 2.3 | 2.3 | 2.4 | 2.4 | 2.5 | 2.5 | 2.5 | |

| Total weight kg | 4500 | 5600 | 5300 | 6400 | 6200 | 7500 | 14000 | |

Previous: GFG series high-efficiency boiling dryer

Drying equipment has a wide range of applications in the chemical and pharmaceutical industries, and its main f…

Spray dryer, as a kind of high-efficiency, continuous drying equipment, has shown significant application advan…

Chinese medicine extract spray dryer does have some limitations in the application, these limitations mainly st…

The drying time of the belt dryer has a significant effect on the product recovery. The following is a detailed…

Tel

Tel

Phone: +0086-13915898166

Tel: +0086-0519-88908166

E-mail

E-mail

Address

Address

Zhenglu Industrial Park, Tianning

Economic Development Zone,

Changzhou City, Jiangsu Province,

China

Long press the QR code to open

GIN WANT