Category: Drying equipment

Introduction: Working principle The hot air tangent enters the bottom of the dryer, forming a strong rotating wind field driven by the mixer. The paste like material enters the dryer through a spiral feeder. Under the strong action of high-speed rotating stirring p…

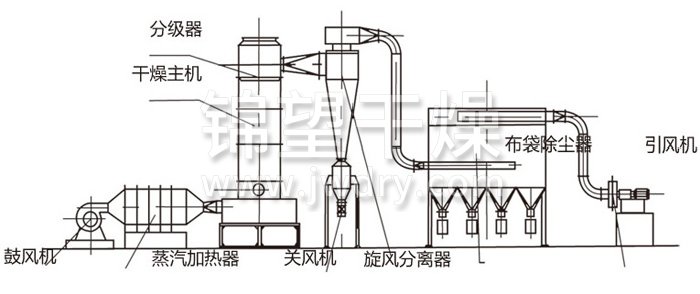

The hot air tangent enters the bottom of the dryer, forming a strong rotating wind field driven by the mixer. The paste like material enters the dryer through a spiral feeder. Under the strong action of high-speed rotating stirring paddles, the material is dispersed under impact, friction, and shear forces. The block like material is quickly crushed, fully in contact with hot air, heated, and dried. The dehydrated dry material rises with the hot airflow, and the grading ring intercepts the large particles. The small particles are discharged from the center of the ring outside the dryer and recycled by the cyclone separator and dust collector. The partially dried or large materials are thrown towards the wall by centrifugal force, and then fall back to the bottom for crushing and drying.

| model | XSG-2 | XSG-4 | XSG-6 | XSG-8 | XSG-10 | XSG-12 | XSG-16 | XSG-20 |

| Host inner diameter mm | 200 | 400 | 600 | 800 | 1000 | 1200 | 1600 | 2000 |

| Air volume M3/h | 350-500 | 1150-2000 | 2450-4500 | 4450-7550 | 7000-12500 | 10000-20000 | 18000-36000 | 28200-56500 |

| Evaporated water content kg/h | 12-17 | 40-70 | 80-150 | 150-250 | 230-450 | 300-600 | 600-1000 | 1000-1500 |

| Installed capacity kw | 10 | 20 | 40 | 65 | 85 | 105 | 150 | 230 |

| Upper height limit m | 4.0 | 4.8 | 5.8 | 6.5 | 7.1 | 7.8 | 8.8 | 10.1 |

| Floor area m2 | 15 | 20 | 28 | 35 | 40 | 52 | 80 | 150 |

Note: 1. Moisture evaporation refers to the amount of water evaporated per hour at an inlet temperature of 180 ℃ and an outlet temperature of 80 ℃. 2. In addition to the above models, special designs can be made for users. 3. The above installed capacity is standard and can be significantly reduced according to different power combinations of materials.

| Name | stearic acid | Aluminum hydroxide | Zinc Carbonate | monosultap | TMTD | DSD Acid | Iron oxide red | Antimony dioxide | Cuprous chloride | White too black |

| Inlet air temperature ℃ | 150 | 180 | 150 | 120 | 140 | 150 | 200 | 180 | 200 | 280 |

| Initial moisture content% | 80 | 55 | 80 | 30 | 65 | 60 | 60 | 45 | 30 | 85 |

| Final moisture content% | 0.5 | 1.5 | 1.0 | 1.0 | 0.5 | 0.5 | 0.5 | 1.0 | 3.0 | 5.0 |

| Actual drying capacity kg/h | 140-160 | 250-280 | 130-170 | 80-110 | 80-120 | 80-120 | 300-350 | 280-320 | 290-310 | 250-300 |

| Name | accelerator |

Oil solubl e ink |

Manganese zinc substituted acid |

Phthalocyanine blue |

calciu m citrate |

ultrafine calcium carbonate |

mud conditioner |

Sodium Dioxyisocyanurate |

Sodium trioxyisocyanurate |

|

Inlet air temperature ℃ |

150 | 150 | 120 | 150 | 140 | 160 | 200 | 180 | 150 |

|

Initial moisture content% |

60 | 45 | 30 | 55 | 40 | 70 | 75 | 25 | 30 |

|

Final moisture content% |

0.5 | 2.0 | 1.0 | 1.0 | 1.0 | 1.5 | 5.0 | 0.2-2 | 1.0 |

|

Actual drying capacity kg/h |

80-110 | 350-380 | 120-150 | 160-180 | 300-350 | 430-470 | 290-310 | 80-120 | 90-150 |

Previous: None

Drying equipment has a wide range of applications in the chemical and pharmaceutical industries, and its main f…

Spray dryer, as a kind of high-efficiency, continuous drying equipment, has shown significant application advan…

Chinese medicine extract spray dryer does have some limitations in the application, these limitations mainly st…

The drying time of the belt dryer has a significant effect on the product recovery. The following is a detailed…

Tel

Tel

Phone: +0086-13915898166

Tel: +0086-0519-88908166

E-mail

E-mail

Address

Address

Zhenglu Industrial Park, Tianning

Economic Development Zone,

Changzhou City, Jiangsu Province,

China

Long press the QR code to open

GIN WANT