Category: Drying equipment

Introduction: Working principleThe material enters the machine from the feed inlet, and under the action of vibration, it is thrown along the horizontal fluidized bed and continuously moves forward. After the hot air passes through the fluidized bed and exchanges h…

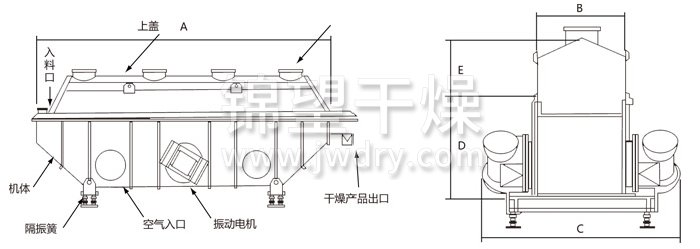

| Size/Model | A | B | C | D | E | F | Weight (kg) |

| GZQ3×0.30 | 3000 | 300 | 1350 | 900 | 430 | 1650 | 1250 |

| GZQ4.5×0.30 | 4500 | 300 | 1350 | 900 | 430 | 1650 | 1250 |

| GZQ4.5×0.45 | 4500 | 450 | 1550 | 950 | 430 | 1700 | 1670 |

| GZQ4.5×0.60 | 4500 | 600 | 1650 | 950 | 430 | 1700 | 1670 |

| GZQ6×0.45 | 6000 | 450 | 1650 | 950 | 430 | 1700 | 2100 |

| GZQ6×0.60 | 6000 | 600 | 1700 | 1000 | 500 | 1700 | 2410 |

| GZQ6×0.75 | 6000 | 750 | 1850 | 1000 | 600 | 1850 | 2840 |

| GZQ6×0.9 | 6000 | 900 | 2000 | 1000 | 600 | 1850 | 3160 |

| GZQ7.5×0.60 | 7500 | 600 | 1850 | 1000 | 600 | 1850 | 3200 |

| GZQ7.5×0.75 | 7500 | 750 | 2000 | 1000 | 600 | 1850 | 3600 |

| GZQ7.5×0.9 | 7500 | 900 | 2100 | 1000 | 600 | 1850 | 4140 |

| GZQ7.5×1.2 | 7500 | 1200 | 2500 | 1150 | 800 | 2050 | 5190 |

| model |

Fluidized bed area (M2) |

inlet ai rtemperature(oC) |

Air outlet temperature(oC) |

Water evaporation capacity(kg) |

VIBRATION MOTOR | |

| model | Power Kw | |||||

| GZQ3×0.30 | 0.9 | 70-140 | 40-70 | 20-35 | ZDS31-6 | 0.8×2 |

| GZQ4.5×0.30 | 1.35 | 70-140 | 40-70 | 35-50 | ZDS31-6 | 0.8×2 |

| GZQ4.5×0.45 | 2.025 | 70-140 | 40-70 | 50-70 | ZDS32-6 | 1.1×2 |

| GZQ4.5×0.60 | 2.7 | 70-140 | 40-70 | 70-90 | ZDS32-6 | 1.1×2 |

| GZQ6×0.45 | 2.7 | 70-140 | 40-70 | 80-100 | ZDS41-6 | 1.5×2 |

| GZQ6×0.60 | 3.6 | 70-140 | 40-70 | 100-130 | ZDS41-6 | 1.5×2 |

| GZQ6×0.75 | 4.5 | 70-140 | 40-70 | 120-140 | ZDS42-6 | 2.2×2 |

| GZQ6×0.9 | 5.4 | 70-140 | 40-70 | 140-170 | ZDS42-6 | 2.2×2 |

| GZQ7.5×0.60 | 4.5 | 70-140 | 40-70 | 130-150 | ZDS42-6 | 2.2×2 |

| GZQ7.5×0.75 | 5.625 | 70-140 | 40-70 | 150-180 | ZDS51-6 | 3.0×2 |

| GZQ7.5×0.9 | 6.75 | 70-140 | 40-70 | 160-210 | ZDS51-6 | 3.0×2 |

| GZQ7.5×1.2 | 9 | 70-140 | 40-70 | 200-260 | ZDS51-6 | 3.0×2 |

★The above evaporation capacity is the upper limit of evaporation capacity.

Drying equipment has a wide range of applications in the chemical and pharmaceutical industries, and its main f…

Spray dryer, as a kind of high-efficiency, continuous drying equipment, has shown significant application advan…

Chinese medicine extract spray dryer does have some limitations in the application, these limitations mainly st…

The drying time of the belt dryer has a significant effect on the product recovery. The following is a detailed…

Tel

Tel

Phone: +0086-13915898166

Tel: +0086-0519-88908166

E-mail

E-mail

Address

Address

Zhenglu Industrial Park, Tianning

Economic Development Zone,

Changzhou City, Jiangsu Province,

China

Long press the QR code to open

GIN WANT