Category: Drying equipment

Introduction: OverviewSZG double cone vacuum dryer is a new generation drying device developed by our factory in combination with similar domestic product technology. The double cone vacuum adopts a belt chain elastic connection method, so the equipment runs smooth…

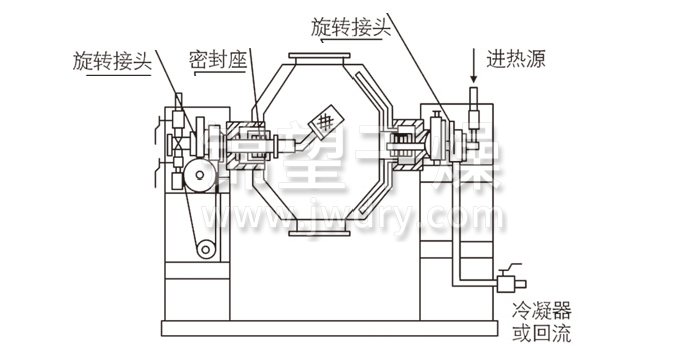

SZG double cone vacuum dryer is a new generation drying device developed by our factory in combination with similar domestic product technology. The double cone vacuum adopts a belt chain elastic connection method, so the equipment runs smoothly. The specially designed process fully reflects the good concentricity of the two shafts, and reliable mechanical seals or rotary joints are used for the heating medium and vacuum system. On this basis, we developed SZG-A, which can perform both stepless speed regulation and constant temperature control.

As a professional drying equipment manufacturer, our products range from high-temperature heat transfer oil as the heat medium, medium temperature steam, and low-temperature hot water. When drying sticky materials, our factory will specially design a "board copying" mechanism or set up rolling balls in the tank for you.

| Name/Specification | 100 | 350 | 500 | 750 | 1000 |

| Tank volume | 100 | 350 | 500 | 750 | 1000 |

| Loading volume (L) | ≤50 | ≤175 | ≤250 | ≤375 | ≤500 |

| Heating area (m2) | 1.16 | 2 | 2.63 | 3.5 | 4.61 |

| Speed (rpm) | 4 - 6 | ||||

| Motor power (kW) | 0.75 | 1.1 | 1.5 | 2 | 3 |

| Long footprint × Width (mm) | 2160×800 | 2260×800 | 2350×800 | 2560×1000 | 2860×1300 |

| Rotation height (mm) | 1750 | 2100 | 2250 | 2490 | 2800 |

|

Design pressure inside the tank (Mpa) |

-0.1-0.15 | ||||

| Jacket design pressure (Mpa) | ≤0.3 | ||||

| Working temperature (℃) | Inside the tank ≤ 85 jacket ≤ 140 | ||||

|

When using the condenser, the vacuum pump |

2X-15A | 2X-15A | 2X-30A | 2X-30A | 2X-70A |

| Model, power | 2KW | 2KW | 3KW | 3KW | 505KW |

|

When the condenser is not used, the vacuum pump |

SK-0.4 | SK-0.8 | SK-0.8 | SK-2.7B | SK-2.7B |

| Model, power | 1.5KW | 2.2KW | 2.2KW | 4KW | 4KW |

| Weight (kg) | 800 | 1100 | 1200 | 1500 | 2800 |

| Name/Specification | 1500 | 2000 | 3500 | 4500 | 5000 |

| Tank volume | 1500 | 2000 | 3500 | 4500 | 5000 |

| Loading volume (L) | ≤750 | ≤1000 | ≤1750 | ≤2250 | ≤2500 |

| Heating area (m2) | 5.58 | 7.5 | 11.2 | 13.1 | 14.1 |

| Speed (rpm) | 4 - 6 | ||||

| Motor power (kW) | 3 | 4 | 5.5 | 7.5 | 11 |

| Long footprint × Width (mm) | 3060×1300 | 3260×1400 | 3760×1800 | 3960×2000 | 4400×2500 |

| Rotation height (mm) | 2940 | 2990 | 3490 | 4100 | 4200 |

|

Design pressure inside the tank (Mpa) |

-0.1-0.15 | ||||

| Jacket design pressure (Mpa) | ≤0.3 | ||||

| Working temperature (℃) | -0.1-0.15 | ||||

|

When using the condenser, the vacuum pump |

JZJX300-8 | JZJX300-4 | JZJX600-8 | JZJX600-4 | JZJX300-4 |

| Model, power | 7KW | 9.5KW | 11KW | 20.5KW | 22KW |

|

When the condenser is not used, the vacuum pump |

SK-3 | SK-6 | SK-6 | SK-9 | SK-10 |

| Model, power | 5.5KW | 11KW | 11KW | 15KW | 18.5KW |

| Weight (kg) | 3300 | 3600 | 6400 | 7500 | 8600 |

Note: For materials with significant volume changes before and after drying, the loading coefficient can be appropriately increased or reduced.

Drying equipment has a wide range of applications in the chemical and pharmaceutical industries, and its main f…

Spray dryer, as a kind of high-efficiency, continuous drying equipment, has shown significant application advan…

Chinese medicine extract spray dryer does have some limitations in the application, these limitations mainly st…

The drying time of the belt dryer has a significant effect on the product recovery. The following is a detailed…

Tel

Tel

Phone: +0086-13915898166

Tel: +0086-0519-88908166

E-mail

E-mail

Address

Address

Zhenglu Industrial Park, Tianning

Economic Development Zone,

Changzhou City, Jiangsu Province,

China

Long press the QR code to open

GIN WANT