Category: Drying equipment

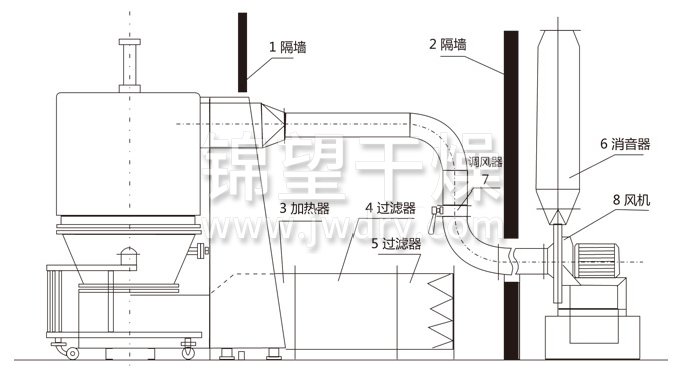

Introduction: Working principleAfter being heated and purified, the air is introduced from the bottom by an induced draft fan and passes through the mesh plate of the hopper. In the studio, fluidization is formed through stirring and negative pressure, and the wate…

The fluidized bed has a circular structure to avoid dead corners.

The hopper is equipped with stirring to avoid the agglomeration of damp materials and the formation of ditch flow during drying.

The use of tipping particles is convenient, rapid, and thorough, and an automatic feeding and discharging system can also be designed according to requirements.

Seal the negative pressure operation, and the airflow is filtered. Easy to operate and clean.

The drying speed is fast, the temperature is uniform, and the drying time for each batch is generally 20-30 minutes, depending on the material.

|

project |

model | ||||||

| Feeding (kg) | 60 | 100 | 120 | 150 | 200 | 300 | 500 |

| Fan power (kW) | 7.5 | 11 | 15 | 18.5 | 22 | 30 | 45 |

| Mixing power (kW) | 0.55 | 1.1 | 1.1 | 1.1 | 1.1 | 1.5 | 2.2 |

| Mixing speed (rpm) | 8~11 | ||||||

| Steam consumption (kg/h) | 141 | 170 | 170 | 240 | 282 | 366 | 451 |

| Operation time (min) | 15-30(Revised according to material characteristics) | ||||||

| Host height | 2700 | 2900 | 2900 | 2900 | 2900 | 3300 | 3500 |

Previous: XF series horizontal boiling dryer

Drying equipment has a wide range of applications in the chemical and pharmaceutical industries, and its main f…

Spray dryer, as a kind of high-efficiency, continuous drying equipment, has shown significant application advan…

Chinese medicine extract spray dryer does have some limitations in the application, these limitations mainly st…

The drying time of the belt dryer has a significant effect on the product recovery. The following is a detailed…

Tel

Tel

Phone: +0086-13915898166

Tel: +0086-0519-88908166

E-mail

E-mail

Address

Address

Zhenglu Industrial Park, Tianning

Economic Development Zone,

Changzhou City, Jiangsu Province,

China

Long press the QR code to open

GIN WANT