Titanium dioxide is an important inorganic chemical pigment with non-toxicity, zui good opacity, zui good whiteness and brightness, which is regarded as a kind of white pigment with better performance at present, and it can provide good covering power, whiteness and gloss, so as to make coatings have excellent decorative and protective properties, and it is widely used in all kinds of coating products such as architectural coatings, automotive coatings, marine coatings and so on. In the plastics industry, it can improve the hardness, heat resistance, weather resistance and gloss of plastic products, and at the same time, it can also reduce the transparency of plastic products, so that it has a better covering effect, and it is commonly used in the production of plastic films, plastic pipes, plastic profiles and other plastic products. In recent years, the rapid expansion of domestic titanium dioxide production capacity, while overseas giants in the titanium ore, energy and other prices continue to be high to speed up the exit from the titanium dioxide market, the export of domestic products ushered in a golden period of development. However, the industry is also facing some challenges, such as the tight supply of raw materials, environmental protection pressure. In the future, the titanium dioxide industry will develop in the direction of high performance, environmental protection and specialization. With the emphasis on environmental protection and resource conservation, the development of low-pollution, low-energy production processes and high-performance, multi-functional titanium dioxide products will become the focus of the industry's development.

The market demand for titanium dioxide performance continues to improve, the future will further develop high-performance titanium dioxide products with higher hiding power, better weather resistance, better dispersion and gloss, in order to meet the gao end of the coatings, plastics, printing ink and other areas of the strict requirements of product quality, to improve the competitiveness of China's titanium dioxide products in the international market, to replace the imported gao end products. Titanium dioxide production process has high energy consumption, the future enterprise will increase the research and application of energy recycling technology. Jinwang drying development of titanium dioxide high temperature flash dryer adopts energy-saving equipment and process, reduce energy consumption, improve energy utilization efficiency, reduce production costs and carbon emissions. The new process not only helps the enterprise to take the advantage in the market competition, but also meets the market demand for high-quality, environmentally friendly titanium dioxide, and further expands the market share.

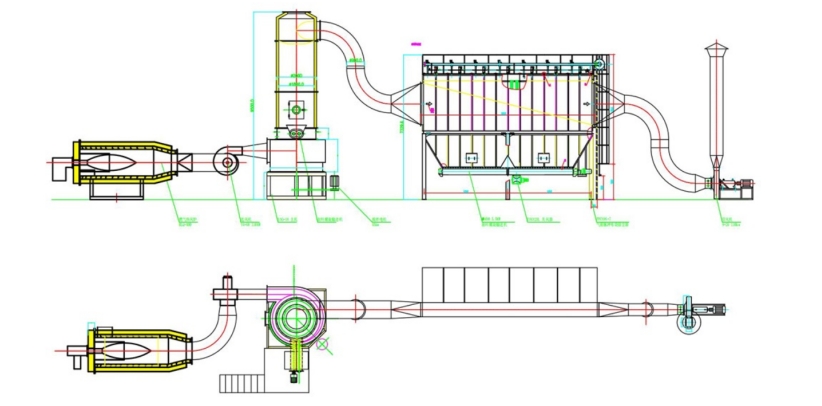

Titanium dioxide high temperature flash dryer process flow

(1) Feeding: Titanium dioxide wet material is usually fed into the flash dryer evenly by the silo through the belt conveyor and other conveying equipment, and then through the spiral feeder. These wet materials are usually titanium dioxide filter cake after pre-treatment such as water washing, with high water content, for example, at about 35%.

(2) Heating and drying: Hot air enters the stirring and crushing drying chamber from the bottom of the dryer by the air inlet with suitable jet speed. The generation of hot air is generally through the hot air furnace to heat the air to the required temperature, the heating method of gas combustion heating, steam heating and so on. Into the dryer hot air and titanium dioxide wet material full contact, under the strong action of the stirrer, the material is centrifugal, shear, collision, friction and other forces and was particulated, lumpy titanium dioxide was quickly crushed, while the hot air with full heat exchange, rapid evaporation of water, to achieve the drying process. Dryer bottom larger wet particles group in the stirrer role is mechanically broken, the wet content is lower, smaller particles are rotating airflow entrainment rise, further drying in the process of rising.

(3) Classification and collection: after drying and crushing of titanium dioxide particles with the hot airflow rising to the top of the dryer classification device. The grading ring and other grading devices will be screened according to the size and weight of titanium dioxide particles, and the products that reach the degree of drying and a certain fineness will be blown out of the grading device, while the larger particles will be retained and fall back to the bottom of the drying chamber to continue to be pulverized and dried, so as to get the titanium dioxide products with uniform particle size.

(4) Receiving dust removal: from the grading device blown out of the dry titanium dioxide fine powder with the airflow into the receiving dust removal system, the system generally includes a cyclone separator and bag duster. The cyclone separator utilizes the principle of centrifugal force to separate most of the titanium dioxide particles from the airflow, and the collected titanium dioxide finished products fall into the collector. Subsequently, the airflow then enters the cloth bag dust collector, filtering the remaining fine dust through the cloth bag, so that the clean air is discharged, further improving the collection efficiency and dust removal effect, and preventing the dust emission from polluting the environment.

(5) Exhaust air: the exhaust air after collecting and removing dust is extracted by induced draft fan and discharged into the atmosphere. In some advanced processes, there will also be waste heat recovery and utilization of the tail gas, such as through the air preheater will be used to heat the heat in the tail gas to heat the fresh air, and then used as a combustion air for the hot air furnace, in order to improve the energy utilization rate and reduce the cost of production.

(6) Discharge: the collected dried titanium dioxide product is discharged from the bottom of the cyclone separator and bag filter, and then transported to the finished product storage tank or packaging process through screw conveyor or air inclined chute and other conveying equipments, zui finally get the titanium dioxide product that meets the quality requirements.

Titanium dioxide high temperature flash dryer equipment advantages

(1) high drying efficiency: hot air tangent into the bottom of the dryer, driven by the stirrer to form a strong rotating wind field, so that the titanium dioxide cake in the high-speed rotation of the stirring paddle under the strong action of the impact, friction and shear and rapid dispersion, and the full contact with the hot air, greatly increasing the contact area of the material and the hot air to strengthen the mass and heat transfer, accelerate the drying speed, can be the cake-like material water content It can dry the water content of filter cake material from 40% to 70% to less than 1% at one time, with short drying time and high efficiency.

(2) Good product quality: the grading ring in the dryer can be screened according to the size and weight of titanium dioxide particles, so that the product to reach the degree of dryness and a certain degree of fineness is blown out of the grading device, while the larger particles are intercepted and re-dried, so as to obtain a uniform particle size of titanium dioxide products, to meet the requirements of different users on the particle size of the product to improve the quality of the product and the added value. In addition, the material temperature rise in the drying process is low, suitable for drying heat-sensitive materials, can effectively prevent material deterioration, to ensure product quality.

(3) Wide range of application: can deal with a variety of forms of materials, such as paste, filter cake, etc., for titanium dioxide production process at different stages of the production of a variety of wet materials can be effective drying, but also to adapt to different moisture content of the material, by adjusting the drying parameters, can be realized on the drying of titanium dioxide filter cake of different moisture content, high application flexibility.

(4) Crushing and drying integration: set drying, crushing function in one, in the drying process at the same time to complete the crushing of the material, without additional crushing equipment, simplify the production process, reduce the investment in equipment and floor space, reduce production costs, improve production efficiency, and to avoid the material in the process of crushing and transfer of pollution and loss.

(5) Stable and reliable operation: the structure of the equipment is reasonably designed, and the components are closely connected, with low vibration and low noise during operation. At the same time, it is equipped with air pressure sealing device and bearing cooling device, which effectively prolongs the service life of the transmission part, reduces the failure rate of the equipment, and ensures the long-term stable operation of the equipment.

(6) Simple operation and maintenance: the control system is advanced, which can realize automatic control and monitoring of the drying process, and the operator only needs to set the relevant parameters according to the needs to realize stable operation with low labor intensity. The structure of the equipment is relatively simple, easy to dismantle and install, convenient for regular cleaning, overhaul and maintenance work, can be timely found and deal with the problems arising from the operation of the equipment.

(7)Good environmental performance: the collection and dust removal system is perfect, consisting of cyclone separator and bag duster, which can effectively separate and collect the dried titanium dioxide particles, so that the dust content of the exhaust gas discharged is in line with environmental protection standards, reducing the pollution of dust to the environment, and realizing clean production.

(8) Energy saving effect is remarkable: in the drying process, the material is not diluted, reducing the heat required for water evaporation, compared with other drying methods, energy consumption is lower. In addition, the equipment has a compact structure and small heat loss, which further improves the energy utilization rate and reduces the production cost.

Titanium dioxide high temperature flash dryer technology optimization

(1) Drying system optimization

Improve the air inlet structure: expand the width of the ring-shaped air inlet at the bottom of the drying chamber, so that the strong airflow along the inverted conical surface rotation upward, to prevent the material from being deposited at the bottom of the machine, to accelerate the rapid dispersion of the material and the speed of heat exchange, to improve the drying efficiency while realizing energy saving and environmental protection.

Optimize the heating method: adopt more efficient heating element or heating system, such as adopting new type of gas burner, so that the combustion is more adequate, the temperature of the hot air is more uniform and stable, and the temperature can be precisely controlled to reduce the waste of energy and improve the drying quality.

Increase insulation measures: add a high-quality insulation layer outside the drying room to reduce heat loss, reduce energy consumption, but also help to maintain the stability of the temperature inside the drying room, so that the titanium dioxide drying process is more uniform, and further improve product quality.

(2) Equipment structure optimization

Increase the hollowing port: Increase the hollowing port on the main flash steamer to facilitate the cleaning of the internal blockage of the material, reduce equipment failure and downtime, and improve the stability of equipment operation and production efficiency.

Improve the transmission mechanism: optimize the design of the transmission mechanism, such as the use of more reasonable gear transmission, belt transmission or coupling connection, improve transmission efficiency, reduce equipment vibration and noise. At the same time, improve the cooling method of the transmission mechanism to prolong the service life of the equipment.

Optimize the overall layout: optimize the overall structure of the dryer to make it more compact and reasonable, and reduce the footprint and space occupation. In addition, it should also consider the convenience of equipment maintenance and repair, and reasonably set up the maintenance door, observation window, manhole, etc., so that it is convenient for the operators to carry out the daily inspection, maintenance and repair work of the equipment.

(3) Stirring and crushing system optimization

Improve the mixer design: adjust the shape, angle and number of mixing leaves to make the mixing more uniform and sufficient, and improve the crushing effect of materials and the contact area with hot air. For example, the stirring blade is designed into a curved shape to increase the lifting and throwing effect on the material, so that the distribution of the material in the drying chamber is more uniform, and the process of mass and heat transfer is strengthened.

Improve the mixing speed and power: according to the characteristics of titanium dioxide and drying requirements, appropriately increase the speed and power of the stirrer, enhance the shear, collision and friction on the material to accelerate the crushing and drying speed of lumpy materials, but need to pay attention to avoiding too high a rotational speed leading to excessive crushing of the material or increased wear and tear of the equipment.

Adopt frequency conversion speed control technology: through frequency conversion speed control device to control the speed of the mixer, according to different drying stages and material state flexible adjustment of the mixing speed, in order to ensure that the drying effect at the same time, reduce energy consumption and equipment operating costs.

(4) Classification system optimization

Optimize the design of grading ring: optimize the structure and size of grading ring to improve the grading accuracy and efficiency, so that the particle size of the product is more uniform and meet the requirements. For example, the use of multi-stage grading ring structure, or adjust the aperture of the grading ring, spacing and other parameters, in order to better screen out different particle sizes of titanium dioxide particles.

The introduction of dynamic classification technology: the use of airflow or mechanical devices generated by the centrifugal force, inertia force, etc., to achieve dynamic classification of materials, so that the classification process is more refined que, stable, and able to effectively separate the qualified products and materials that do not meet the drying standards, improve product quality and production efficiency.

(5) Optimization of receiving and dust removal system

Improve the collection efficiency: Improve the structure and performance of cyclone separator and bag filter to improve the capture efficiency of titanium dioxide particles and reduce product loss. For example, optimize the inlet shape, cylinder diameter and height and other parameters of the cyclone separator to improve its separation effect; use higher filtration precision and better permeability of the bag material to improve the dust removal efficiency of the bag filter.

Prevent dust clogging: set up anti-clogging devices, such as vibrators, air cannons, etc., in the receiving and dust removal system, and clean the equipment regularly to prevent titanium dioxide dust from accumulating and clogging in the pipelines, valves and dust collectors, and ensure the normal operation of the system.

Tail gas treatment upgrade: Increase tail gas purification equipment, such as activated carbon adsorption device, catalytic combustion device, etc., to further reduce the content of harmful substances in the tail gas, so as to meet the more stringent environmental protection emission standards, and to reduce the pollution of the environment.

(6) Control system optimization

Realize automatic control: adopt advanced sensor technology, automatic instrumentation and PLC control system to realize real-time monitoring and automatic control of temperature, humidity, wind speed, pressure and other parameters in the drying process, so as to ensure the stability of the drying process and consistent product quality. Through the preset control program, the operating parameters of the equipment can be adjusted automatically according to different material characteristics and drying requirements, so as to improve the production efficiency and product quality stability.

Remote monitoring and diagnosis: Equipped with remote monitoring system, it realizes remote operation, monitoring and fault diagnosis of the equipment through network technology. The operator can carry out real-time monitoring and management of the equipment in the control center which is far away from the site, discover and solve the problems in the operation of the equipment in time, reduce the cost of equipment maintenance and downtime, and improve the continuity and reliability of production.

Data recording and analysis: Record and store the data in the drying process, establish a database, and analyze and mine the data through data analysis software to provide a basis for optimizing the production process and improving the performance of the equipment. For example, by analyzing the drying data of different batches of titanium dioxide, we can find out the best combination of drying parameters and realize refined production management.

Tel

Tel E-mail

E-mail Address

Address