Chemical fiber titanium dioxide, that is, polyester fiber special grade titanium dioxide, is a kind of titanium dioxide added to chemical fibers and man-made fibers to play the role of matting, can effectively eliminate the luster of the surface of the chemical fiber, so that the fiber presents a soft, natural appearance, which is essential for some need to avoid reflections or the pursuit of a specific visual effect of the fiber products, such as certain high-grade apparel fabrics, home textile products and so on. Its refractive index is close to two times that of polyester, a characteristic that makes it better able to scatter and absorb light in the fiber, thus enhancing the matting effect. In the production and use of chemical fibers, chemical fiber titanium dioxide is not easy to react with other chemicals, to maintain the stability of its performance, will not affect the quality and performance of the fiber due to chemical reactions. High-quality chemical fiber titanium dioxide in the fiber production process can be evenly dispersed in the fiber matrix to ensure the consistency of the matting effect and the uniformity of the fiber performance, to avoid defects on the surface of the fiber due to agglomeration of titanium dioxide particles or uneven performance and other issues. Chemical fiber titanium dioxide is mainly used in the production of polyester fiber, polyacrylonitrile fiber and other chemical fibers.

In recent years, chemical fibers in the textile, clothing, home textiles and other fields of application is becoming more and more widely used, its performance continues to improve, the market demand continues to grow, for chemical fiber titanium dioxide provides a broad market space, polyester fiber, for example, has the advantages of high strength, good elasticity, wear-resistant, etc., in the field of apparel, home textiles and other areas of the application of the ever-expanding demand for titanium dioxide for chemical fibers is also increased accordingly. With the continuous improvement of the quality and functional requirements of fiber products, the demand for chemical fiber titanium dioxide products with high performance and high value-added products is also increasing. For example, in high-performance sportswear, outdoor products, automotive interiors and other fields, the need to use chemical fiber titanium dioxide with special properties, such as high weather resistance, high ultraviolet shielding properties, etc., which provides chemical fiber titanium dioxide producers with opportunities to expand to the gao-end market. Driven by the supply-side structural reform, the chemical fiber titanium dioxide industry will also face the opportunity of industrial upgrading and integration. By eliminating backward production capacity, optimizing industrial structure and increasing industry concentration, it will help improve the overall competitiveness of the chemical fiber titanium dioxide industry and promote the healthy development of the market. Research and development of chemical fiber titanium dioxide products with higher performance will be the focus of future development. At the same time, industrial integration will also promote cooperation and innovation among enterprises and accelerate the research and development and popularization and application of new technologies and products. Jinwang Drying continuously improves the drying process of chemical fiber grade titanium dioxide to enhance the quality and performance of chemical fiber titanium dioxide. The newly developed ultra-high speed centrifugal spray dryer for chemical fiber grade titanium dioxide adopts more advanced drying technology, which can produce chemical fiber titanium dioxide products with finer particle size, more uniform distribution and lower impurity content, and improve its dispersion and covering power in the fiber; the chemical fiber titanium dioxide with finer particle size makes use of its small-size effect and quantum effect, which can give better ultraviolet ray shielding performance, anti-bacterial performance and antistatic performance to the fiber products, etc., and satisfy the market of high-end fiber products. To meet the needs of high-end fiber products market, enhance the added value of products and market competitiveness.

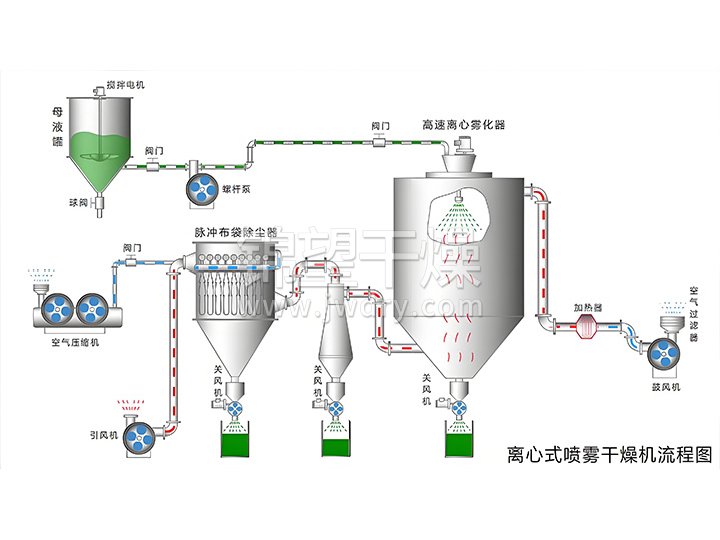

Chemical fiber grade titanium dioxide ultra-high speed centrifugal spray dryer process flow

(1) Feeding stage

Material preparation: the liquid chemical fiber titanium dioxide material to be dried is pre-treated, such as filtering to remove impurities, blending concentration, etc., to ensure the purity and fluidity of the material to meet the requirements of spray drying.

Conveying and feeding: the pre-treated liquid chemical fiber titanium dioxide material will be pumped out from the trough through the feeding pump and conveyed to the high-speed centrifugal atomizer on the top of the dryer through the pipeline. In the feeding process, it is necessary to control the stability of the feeding speed to ensure the atomization effect and the uniformity of the drying process.

(2) Spraying stage

Ultra-high-speed centrifugal atomization: After the liquid chemical fiber titanium dioxide material enters the high-speed centrifugal atomizer, under the action of the centrifugal force of high-speed rotation, the material is rapidly dispersed into extremely small droplets. Atomizer speed is usually up to thousands of revolutions or even tens of thousands of revolutions per minute, the resulting centrifugal force can make the material in the rotating surface stretch for the film, and constantly to the edge of the movement, zui finally left the edge of the formation of atomized state. These tiny droplets of particle size is generally in the tens of microns to hundreds of microns, greatly increasing the contact surface area of the material and hot air.

(3) drying stage

Hot air supply: Meanwhile, the air is filtered and heated to enter the air distributor on the top of the dryer. The temperature of the heated air is usually adjustable between 130℃-300℃. The hot air enters the drying chamber uniformly in a spiral shape and comes into contact with the atomized chemical fiber titanium dioxide droplets in parallel flow.

Moisture evaporation: fog droplets and hot air in the drying room fully mixed, due to the large surface area of the droplets and the contact with the hot air is sufficient, the water in a very short period of time to evaporate quickly. In this process, the hot air as a heat carrier will transfer heat to the droplets, so that the moisture in the droplets absorb heat and vaporize into water vapor, thus realizing the drying of chemical fiber titanium dioxide. Drying time is generally only a few seconds to tens of seconds, can effectively prevent the chemical fiber titanium dioxide due to prolonged heat deterioration or performance degradation and other issues.

(4) Collection stage

Finished product collection: After drying, the finished chemical fiber titanium dioxide product exists in the form of ultrafine powder, which is continuously output from the bag filter under the effect of gravity. The cloth bag dust collector utilizes the principle of precision bag filtration to separate the finished product from the exhaust gas, so that the particles of the finished product settle into the bottom collector, while the exhaust gas continues to rise and be discharged.

Packaging and Storage: The collected finished chemical fiber titanium dioxide products are packaged and stored after the necessary testing and quality control. Packaging is usually selected according to the specific requirements of the product and customer needs, such as plastic bags, woven bags, barrels, etc., to ensure that the product is not damp or contaminated during storage and transportation.

(5) Exhaust gas emission stage

Exhaust gas treatment: The exhaust gas generated during the drying process contains a certain amount of water vapor and a small amount of chemical fiber titanium dioxide dust that has not been completely collected, and it needs to be purified and treated by an exhaust gas treatment system before being discharged. The exhaust gas treatment system usually includes dust collector, scrubber and other equipments, which are used to remove the dust particles and harmful gases in the exhaust gas, so as to make it reach the environmental protection emission standard and reduce the pollution to the environment.

Emission by air: The treated exhaust gas is discharged into the atmosphere by means of a fan. During the discharge process, the temperature, flow rate, dust content and other parameters of the exhaust gas need to be monitored to ensure that the discharge meets the requirements of relevant environmental regulations.

Chemical fiber grade titanium dioxide ultra-high speed centrifugal spray dryer performance characteristics

(1)High drying efficiency

Fast drying speed: the drying process can be completed in a very short time, the material is sprayed by the centrifugal surface area increases, in the high temperature airflow can instantly evaporate 95% ~ 98% of the water, generally only a few seconds to tens of seconds to complete the drying, greatly improving the production efficiency.

Production continuity is good: suitable for continuous large-scale production, can be a steady stream of liquid chemical fiber titanium dioxide material drying into powder or granular finished products, to meet the needs of large-scale production, improve production efficiency.

(2) Excellent product quality:

The produced chemical fiber titanium dioxide products have good dispersibility, fluidity and solubility, its particle size, bulkiness, moisture and other indicators within a certain range can be adjusted by changing the operating conditions, high purity of the product to meet the chemical fiber production of titanium dioxide to meet the stringent requirements for the quality of titanium dioxide, so as to be better used in the production of polyester fibers, nylon fibers, acrylic fibers and other production, to improve the whiteness of the fibers, gloss, coverage and weather resistance and other properties. Weather resistance and other properties.

(3) Process simplification:

The chemical fiber titanium white liquid material with moisture content of 40%~90% can be dried directly into powder by one time, without the need for crushing, screening and other cumbersome processes, which reduces the production link and production cost, and also reduces the dust pollution and material loss in the production process, and improves the production efficiency and quality stability of the product.

(4) Environmental protection and energy saving:

Higher thermal efficiency: In the drying process, the hot air and the material are in parallel flow contact, the thermal efficiency is relatively high and the energy consumption is relatively low, which can save the energy cost to a certain extent.

Exhaust gas treatment up to standard: the equipment is equipped with an effective exhaust gas treatment system, which can purify and treat the exhaust gas produced in the drying process and reduce the dust emission, so that it can reach the environmental protection emission standard, meet the environmental protection requirements and reduce the pollution of the environment.

(5) Convenient operation and control:

Equipped with advanced automatic control system, it can realize fineque control and real-time monitoring of temperature, pressure, rotating speed, feeding speed and other parameters in the drying process to ensure stable operation of the equipment and controllability of product quality, and also has the functions of fault alarm and automatic protection, which improves the safety and reliability of the equipment and reduces the labor intensity of the operators.

Optimization and improvement of chemical fiber grade titanium dioxide ultra-high speed centrifugal spray dryer

(1) Improve the nature of the material:

Adjust the concentration and viscosity of the material: the concentration and viscosity of chemical fiber titanium dioxide material have a significant effect on the atomization effect. Concentration is too high, the fluidity of the material is poor, it is difficult to form a uniform film on the atomization disk and

Fine droplets; concentration is too low, it will increase the drying cost and time. The best material concentration range can be determined by test, and the material can be diluted or concentrated according to the need. If the viscosity of the material is large, heating, adding diluent and other methods to reduce the viscosity, so that it is easier to atomize.

Filtering impurities: Before feeding, the chemical fiber titanium dioxide material must be strictly filtered to remove the solid impurities. Impurities may clog the nozzle of the atomizer or affect the distribution of the material on the atomization disk, resulting in uneven atomization. Suitable filters, such as screens and cartridges, can be used to ensure the purity of the material.

(2) Feed system improvement:

Precise que control of feeding speed: Use high-precision metering pump or frequency conversion speed control technology to realize the precise que control of feeding speed. Stable and uniform feeding speed helps to ensure the stability of atomization effect and drying quality, and avoid product quality problems caused by fluctuations in feeding speed.

Optimization of material pretreatment: before feeding the chemical fiber titanium dioxide material for finer pretreatment, such as further refinement of filtration, removal of impurities, blending and other operations to ensure that the material into the dryer has good fluidity and stability, which is conducive to improving the atomization effect and drying efficiency, and at the same time reduce the wear and tear on the equipment and the risk of blockage.

(3) Optimize the atomizer design:

Select the appropriate atomizing disc: according to the characteristics of chemical fiber titanium dioxide materials and drying requirements, select the appropriate diameter, shape and material of the atomizing disc. Larger diameter atomizing disc can provide greater centrifugal force, which is conducive to atomization; different shapes of atomizing discs, such as flat bottom, convex bottom, concave bottom, etc., will also have an impact on the atomization effect. In addition, the material of the atomizing disc should have good abrasion resistance, corrosion resistance and thermal conductivity to ensure its stable performance and service life.

Improve the structure of the atomization disc: optimize the structure of the atomization disc, such as increasing the guide groove, changing the shape of the nozzle, etc., which can make the distribution of the material liquid in the atomization disc more uniform and improve the atomization effect. The flow channel can guide the liquid in the centrifugal force to flow more orderly to the edge, the formation of finer and more uniform droplets; optimize the shape of the nozzle can make the liquid sprayed out of the angle and speed is more reasonable, to further improve the atomization effect.

(4) Heating system optimization

Improve the temperature control precision of the hot air into the tower: install more precise temperature sensors and advanced temperature control system, real-time monitoring and precise control of the hot air into the tower temperature. Through precise control of the temperature of the feed tower, the thermal efficiency can be further improved and the energy consumption can be reduced under the premise of guaranteeing the drying effect.

Optimize the hot air circulation system: design a more reasonable hot air circulation path and method, so that the hot air can make full use of its thermal energy and reduce heat loss. For example, a counter-flow hot air circulation system can be used, so that the hot air and materials to form a better heat exchange, improve the utilization rate of heat energy. At the same time, strengthen the sealing performance of the hot air circulation system to prevent leakage of hot air, and further improve the efficiency of energy utilization.

Waste heat recovery and utilization: increase the waste heat recovery device, the waste heat generated in the drying process for recycling and reuse. Waste heat can be transferred to the cold air or materials entering the dryer through the heat exchanger to preheat the materials or increase the temperature of the incoming air, thus reducing energy consumption and lowering production costs.

(5) Optimization of equipment structure design

Stabilization of hot air temperature and wind speed: hot air temperature and wind speed are important factors affecting the atomization effect and drying process. Appropriately increase the hot air temperature, can accelerate the water evaporation rate, so that the droplets in the drying process is easier to break into smaller particles, thus improving the atomization effect. However, care should be taken to avoid excessive temperature leading to material deterioration or adverse effects. At the same time, maintain a stable wind speed, can make the hot air and liquid droplets fully contact, promote water evaporation and atomization process.

Optimize the airflow distribution in the drying chamber: Reasonably design the structure of the drying chamber and the airflow channel, so that the hot air can be evenly distributed in the drying chamber to form a stable airflow field. It can guide the flow direction of hot air and reduce the eddy current and dead angle of airflow by setting devices such as deflector plate and even wind plate, so as to ensure that the liquid droplets in the drying chamber can fully and evenly contact with the hot air, and improve the atomization and drying effect. Optimize the shape and size of the drying chamber: according to the hot air flow law and material drying characteristics, the shape and size of the drying chamber to optimize the design. Reasonable drying chamber structure can make the hot air more evenly distributed in the drying chamber, with the droplets in full contact, reduce the drying dead space, improve the uniformity and efficiency of drying. In addition, you can also consider setting up a deflector or disturbance element in the drying chamber to enhance the mixing effect of hot air and droplets and further improve the drying effect.

(6) Control system upgrade

Automation and intelligent control: Introduce advanced automation control system, such as PLC, DCS, etc., to realize comprehensive automation control of the dryer. By presetting the drying process parameters, the system can automatically adjust the feeding speed, atomizer speed, hot air temperature, air volume and other parameters to ensure that the drying process is always in zui state. At the same time, it can also be equipped with remote monitoring and fault diagnosis function, which is convenient for the operator to understand the real-time operation of the equipment, discover and deal with the faults in time, and improve the intelligent level of production and the reliability of the equipment.

Data acquisition and analysis: strengthen the acquisition and analysis of various data in the drying process, such as temperature, humidity, pressure, flow, material concentration and other parameters. Through the analysis of a large number of data, we can gain a deeper understanding of the laws and characteristics of the drying process, and provide a basis for optimizing process parameters and improving product quality. In addition, the results of data analysis can also be used to establish a prediction model, predict the possible problems of the equipment in advance, realize preventive maintenance and extend the service life of the equipment.

Tel

Tel E-mail

E-mail Address

Address