The market demand for high-performance organic pigments has shown rapid growth as downstream industries continue to improve product quality and performance requirements. High-performance organic pigments have high added value and technical barriers, and the development of domestic enterprises in this field will help enhance the overall competitiveness of the industry and gain a larger market share. The low-temperature belt dryer for high-performance organic pigments produced by Jinwang solves the problems of low productivity and unstable product quality that exist in the traditional drying of organic pigments. The new equipment adopts a continuous production process, which makes each production link such as charging, extruding, drying, cooling, dust removal, etc. carry out continuously, improves the production efficiency, reduces the production cost, and can better control the consistency of product quality. At the same time, Jinwang Drying provides professional technical support and after-sales service to help customers solve problems in the process of use, improve customer satisfaction and loyalty, enhance the market competitiveness of the enterprise, and provide customers with high-performance organic pigment post-treatment process of the overall solution.

Organic Pigment Low Temperature Belt Dryer Process Flow

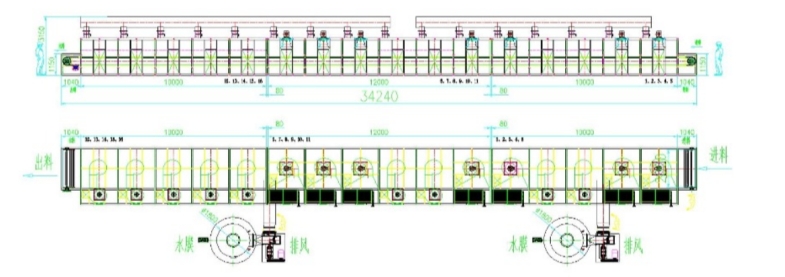

Organic pigment low-temperature belt dryer includes pigment molding system, fabric system, conveying system, heating unit, exhaust gas treatment system, electrical control system and so on. The materials are first made into specific shapes, such as strips, through the pigment molding system, and then evenly spread on the conveying mesh belt by the fabric system. The heating unit provides heat, so that the hot air from above and below the mesh belt is forced to input, and fully contact with the material, so that the internal moisture of the material spreads and evaporates, thus realizing drying. The exhaust gas treatment system then treats the waste gas generated during the drying process and discharges it after reaching the standard.

(1) Pigment molding: Firstly, the filter cake or paste material of organic pigment will be processed through the pigment molding system, so as to make it form a specific shape, such as granule, column or strip. Common molding methods include extrusion molding, granulation molding, etc. This can increase the heat area of the material and improve the drying efficiency, while avoiding the disadvantages brought about by the viscosity of the material.

(2) Fabrication: The material after molding is evenly spread on the mesh belt of the belt dryer through the automatic spreading device. The uniformity of spreading is crucial to the drying effect, which ensures that the materials can be heated evenly in the drying process, thus guaranteeing that the moisture content of the dried pigment is consistent and the product quality is stable.

(3) Drying: The mesh belt moves slowly and sends the material into the drying chamber. In the drying room, the hot air is forced in from above and below the mesh belt to fully contact with the material. The temperature of the hot air is usually controlled in a low range to meet the requirements of low temperature drying of organic pigments, to avoid degradation or deterioration of pigment properties due to high temperature. The moisture inside the material spreads and evaporates continuously under the action of the hot air, thus realizing the purpose of drying. During the drying process, the temperature of the hot air, wind speed and the residence time of the material in the drying room and other parameters will be adjusted and controlled according to the type of pigment, moisture content, drying requirements and other factors.

(4) Tail gas treatment: The exhaust gas produced in the drying process contains certain moisture and organic volatiles and other pollutants, which need to be treated by the tail gas treatment system. Tail gas treatment methods include condensation, adsorption, combustion and so on, in order to remove harmful substances in the exhaust gas, so that it meets the environmental protection emission standards and then discharged into the atmosphere to reduce the pollution of the environment.

(5) Cooling and discharging: After drying, the material has a high temperature and needs to be cooled for subsequent packaging and storage. Some belt dryers are equipped with a cooling section to cool the material quickly by air or water cooling. After the cooled material reaches the required temperature and humidity, it is conveyed to the discharge port by the mesh belt to complete the whole drying process.

(6) Cleaning and maintenance: After finishing the drying of a batch of materials, the equipment needs to be cleaned to prevent material residues and cross-contamination. The mesh belt, drying chamber, radiator and other parts of the belt dryer need to be cleaned and maintained on a regular basis to ensure the normal operation of the equipment and the stability of product quality.

Organic Pigment Low Temperature Belt Dryer Technical Advantages

(1) Product quality guarantee

Low-temperature drying: The drying temperature can be precisely controlled, and the drying of materials can be realized under low-temperature conditions, which effectively avoids the problem of the decline or deterioration of the organic pigment's color, luster, strength, etc. due to high temperature, and ensures that the pigments after drying have a good quality to meet the stringent requirements of the high-end market for the quality of organic pigments.

Uniformity of drying: the materials are evenly distributed on the mesh belt, and the hot air is heated from the upper and lower sides at the same time, so that the materials are heated more uniformly, and the dried pigments have the same moisture content and stable product quality, which is conducive to the subsequent processing and application.

Shape maintenance: the material is moving in a static state during the drying process, almost not destroying the shape of the product, which is conducive to maintaining the integrity of the pigment particles and the distribution of particle size, which is especially important for the production of some organic pigments with high requirements on the shape of the particles and the particle size.

(2)Improvement of production efficiency

Continuous production: Continuous and automatic production can be realized, the material moves continuously on the mesh belt and passes through drying, cooling and other processes in turn without frequent feeding and discharging, which greatly improves the production efficiency and is suitable for the needs of large-scale production.

Fast drying: Although low-temperature drying is adopted, it still has a fast drying speed due to the full contact between the hot air and the material and efficient heat exchange, which can dry the organic pigment to the required moisture content in a short time and shorten the production cycle.

(3)Energy saving and environmental protection

High-efficiency heating: adopting advanced heating method and reasonable ventilation design with high thermal efficiency, it can fully utilize the energy, reduce the waste of energy and lower the production cost. Air recycling: part of the tail gas can be recycled back to the drying system for reuse after treatment, which reduces the introduction of fresh air, further reduces energy consumption, and also reduces the pressure of tail gas treatment, which is in line with the development trend of energy saving and environmental protection.

Waste heat recovery and utilization: focusing on the recovery and recycling of energy in the production process, such as the use of waste heat recovery device, the waste heat generated in the reaction process for preheating raw materials or heating the media in other production processes; optimization of the energy management system, to achieve a reasonable distribution and efficient use of energy to reduce energy consumption in the production process, reducing production costs and the impact on the environment.

(4) Equipment stability and maintenance convenience

Stable structure: the structure of the equipment is relatively simple, mainly composed of pigment molding system, fabric system, conveying system, heating unit, exhaust gas treatment system, electrical control system, etc. The performance of each component is stable and reliable, with a low incidence of faults, which can effectively reduce the downtime of the equipment and ensure the continuity of production.

Convenient cleaning and maintenance: the conveyor belt can be cleaned, and the heating room is separated from the drying room, which is convenient for cleaning the conveyor mesh belt, preventing material residue and cross-contamination, ensuring the purity of the product, and at the same time, it is also conducive to prolonging the service life of the equipment.

(5)High safety performance: drying in a closed or vacuum environment reduces the contact between organic pigments and air, which reduces the safety risks such as dust explosion, and also helps to protect the health and safety of operators.

(6) Cost-effectiveness advantage

Reduce the comprehensive cost: Although the procurement cost of the equipment may be relatively high, it can bring significant economic benefits to the enterprise and reduce the comprehensive production cost in the long run due to its high production efficiency, low energy consumption and maintenance cost, as well as stable product quality.

Adaptation to diversified production: according to different output and material moisture requirements, multiple equipment can be selected for use in series, or by adjusting the parameters of the equipment, to adapt to the drying needs of a variety of organic pigments, with strong flexibility and adaptability, and can be widely used in different scales and types of organic pigment production enterprises.

(7) Application of automation control technology

With the help of advanced automation control technology, such as distributed control system (DCS), programmable logic controller (PLC), etc., the temperature, pressure, flow rate, pH value and other parameters in the production process of organic pigments can be finely controlled to realize the automatic operation and intelligent management of the production process. It can not only improve the stability and safety of production, but also reduce the impact of human factors on product quality, improve production efficiency and product quality stability.

Tel

Tel E-mail

E-mail Address

Address