Category: Chemical Industry

Introduction: Glyphosate is a kind of broad-acting organophosphorus herbicide, in 2021, the global production capacity of glyphosate totaled 1.13 million tons, of which Chinas production capacity amounted to 760,000 tons, accounting for more than 60%.In 2022, the t…

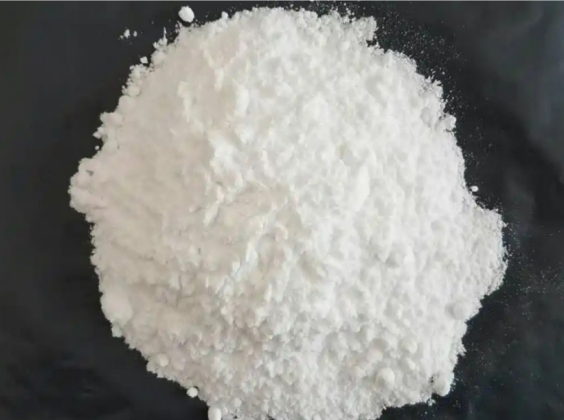

Glyphosate is a kind of broad-acting organophosphorus herbicide, in 2021, the global production capacity of glyphosate totaled 1.13 million tons, of which China's production capacity amounted to 760,000 tons, accounting for more than 60%.In 2022, the total domestic production capacity has exceeded 800,000 tons/year, accounting for 68.72% of the global glyphosate production capacity. With the promotion and application of GM crops in the world, the demand for glyphosate will also increase further. Since glyphosate is a commonly used herbicide in the planting process of glyphosate-resistant GM crops, its market demand is expected to grow with the expansion of the planting area of GM crops. Overseas demand is gradually recovering, such as Brazil, the United States and Argentina and other major glyphosate-consuming countries are expected to gradually enter the replenishment period after the end of glyphosate de-stocking one after another in 2023, which will form a strong support for glyphosate exports, which will in turn drive the overall market demand upward. The trend of glyphosate products to compounding and mixing is becoming more and more obvious, compounding products can not only accelerate the growth of broadleaf weeds, but also improve the cost-effectiveness of glyphosate, which will lead to the further expansion of its market demand, and more growers are inclined to choose compounding herbicides to meet the diversified needs of weed control.

The glyphosate industry has a mature production process and a complete industrial structure, and new entrants face high technical and financial thresholds. Glyphosate is categorized as a restricted industry, and policy restrictions have led to increased barriers to entry, limiting disorderly expansion of production capacity. Producers will continue to carry out R&D and innovation, and devote themselves to process technology innovation. By improving the production process and developing new catalysts, they will realize a continuous decrease in costs, promote industrial upgrading, and improve product quality and market competitiveness. Jinwang improves the process flow of glyphosate drying, increases the drying efficiency and product yield, and continuously optimizes the process parameters, so that the new equipment has more advantages in environmental protection, technology, quality and cost.

The hot air enters into the mixing and crushing drying room from the bottom of the drier with suitable spraying speed by the entrance pipe, and produces strong shearing, blowing and floating and rotating effects on the materials, so the materials are centrifuged, sheared, collided and friction and are micronized, which strengthens the mass and heat transfer. At the bottom of the dryer, the larger and wetter particles are mechanically crushed under the action of the stirrer, and the materials with lower wet content and smaller granularity rise with the rotating airflow, and are further dried in the rising process. As the gas-solid two-phase rotating flow, solid phase inertia than the gas phase, the relative velocity between the solid gas phase is larger, strengthening the mass and heat transfer between the two phases, so the machine has high production intensity.

(1) Feed preparation: Before entering the flash dryer, the glyphosate material needs to be pre-treated, such as filtering, removing impurities, etc., to ensure that the purity and particle size of the material meet the drying requirements. Then, the glyphosate material is evenly added to the feed port of the flash dryer through the screw feeder or other suitable feeding device.

(2) Heating and airflow formation: Turn on the heater to heat the air to the set temperature. The hot air enters the drying chamber from the tangential direction at the bottom of the dryer, forming a high-speed spiral rising airflow, generating a strong centrifugal force, and providing power for drying and conveying the material.

(3) Material drying and crushing: The glyphosate material entering the dryer will fall down first under the action of gravity, and the lumpy material will be crushed into smaller particles rapidly under the action of the high-speed rotating dispersing device at the lower end of the flash mainframe. At the same time, the hot air and material full contact, heat transfer to the material, so that the moisture in the material quickly evaporated. Material particles in the rotating airflow and centrifugal force is thrown to the wall, and the wall of the collision, friction and shear, and further crushed particles, increasing the contact area with the hot air, accelerating the drying speed.

(4) Classification and circulation: the upper part of the dryer is equipped with a classifier, the glyphosate materials with large particles or not fully dried are thrown to the wall by centrifugal force, and fall back to the drying section or the fluidization section through the classifier, continue to receive drying and crushing until the required particle size and humidity; while the dried fine powder particles are taken out by the upper part by the airflow, and enter into the cyclone separator and the cloth bag dust collector to be collected.

(5) Discharge and packaging: After drying and grading, the dried glyphosate product is discharged from the discharge port at the bottom of the dryer and enters the finished product collection device. The collected dried products are inspected and qualified for packaging, storage or further processing.

(6) Tail gas treatment: The tail gas discharged from the cyclone separator and bag filter contains a small amount of dust and water vapor, in order to reduce environmental pollution, it needs to be purified and treated by the tail gas treatment device, such as wet dust collector, activated carbon adsorber, etc., and then discharged into the atmosphere after reaching the standard.

(7) Equipment cleaning and maintenance: After completing the drying operation, the flash dryer needs to be cleaned to remove the residual materials and impurities inside the equipment to prevent clogging and corrosion. At the same time, regular maintenance of the equipment, inspection and replacement of worn parts to ensure the normal operation and service life of the equipment.

(1)High drying efficiency

Strengthen heat and mass transfer: hot air enters from the tangential direction at the bottom, forming a spiral upward airflow, so that the material is fully dispersed in the rotating hot airflow and in close contact with it, and the relative speed of gas and solid phases is large, which strengthens the process of mass and heat transfer and accelerates the drying speed. Material crushing and drying synchronization: the rotating blade or stirring device in the dryer can continuously crush the material, increase the contact area between the material and the hot air, so that the drying efficiency is further improved, and at the same time to avoid the phenomenon of material agglomeration and sticking to the wall, improve the uniformity of drying.

(2)Good product quality

Effective control of particle size and moisture: by adjusting the angle of cyclone sheet, air inlet speed and parameters of classifier, etc., the particle size and moisture content of dried glyphosate product can be finely que controlled to ensure stable product quality and meet different production requirements. Avoiding deterioration of heat-sensitive materials: although the bottom of the main machine is a high-temperature area, it is equipped with a cooling water protection device, so that the heat-sensitive glyphosate materials do not come into direct contact with the hot surface during drying, preventing the materials from scorching and discoloring, and ensuring the quality of the products.

(3)Superior system performance

Small system resistance: the unique design of tangential air inlet of double air ducts avoids the velocity inhomogeneity of the rotating field in the radial flow field and makes the airflow smoother, which reduces the system resistance, reduces energy loss and improves the thermal efficiency. Good airtightness: the drying process is operated under micro-negative pressure or negative pressure, which effectively prevents the material dust from escaping and avoids environmental pollution, and at the same time reduces the loss of materials and improves the safety and economy of production.

(4) High reliability of equipment

Reasonable structural design: the dryer has a compact structure, covers a small area and is easy to install. Its key components such as rotary blades, bearings, etc. are specially designed and processed, which have the advantages of low wear and long service life, reducing the maintenance cost and downtime of the equipment. Good sealing performance: The new sealing structure effectively prevents material leakage and air leakage, which ensures the normal operation of the dryer, and also reduces the pollution to the environment and improves the stability and reliability of the equipment.

(5) Great operating flexibility

Wide range of applicable materials: it is not only suitable for drying glyphosate, but also can be used for drying high humidity, high consistency, high viscosity, heat-sensitive paste, powder or granule materials in chemical, light industry, petrochemical, pharmaceutical, food, mining and other industries, such as dyestuffs, pigments, paints, feeds, fertilizers, chemical fibers, rubber auxiliaries and so on. Strong adjustability: the key control parameters of the equipment, such as air inlet temperature, air inlet volume, material residence time, etc. can be flexibly adjusted according to different material characteristics and drying requirements, in order to adapt to the drying needs of a variety of materials, realizing the function of a multi-purpose machine.

(6)High degree of automation

Equipped with advanced control system: it can realize real-time monitoring and automatic control of temperature, humidity, wind speed, material flow rate and other parameters of the drying process, which ensures the stability of the drying process and the consistency of product quality. At the same time, it can also be linked with upstream and downstream equipment for control, improving the automation level and production efficiency. Simple and convenient operation: the operator only needs to set the relevant parameters through the control panel to realize the automatic operation and monitoring of the equipment, without the need to carry out complex operations and frequent manual intervention, reducing the labor intensity and operation difficulty.

Drying equipment has a wide range of applications in the chemical and pharmaceutical industries, and its main function is…

Spray dryer, as a kind of high-efficiency, continuous drying equipment, has shown significant application advantages in m…

Chinese medicine extract spray dryer does have some limitations in the application, these limitations mainly stem from th…

The drying time of the belt dryer has a significant effect on the product recovery. The following is a detailed analysis …

Tel

Tel

Phone: +0086-13915898166

Tel: +0086-0519-88908166

E-mail

E-mail

Address

Address

Zhenglu Industrial Park, Tianning

Economic Development Zone,

Changzhou City, Jiangsu Province,

China

Long press the QR code to open

GIN WANT