Water dispersible granules (WDG) have been developed in Europe and the United States since the early 1980s. As a safer and commercially attractive alternative to wettable powders and suspending agents, WDG has begun to be developed on a large scale globally, with continuous improvement and refinement of the production process and gradual expansion of its application range. Because of its good safety, no dust, little pollution to the environment, and good dispersibility, suspension and stability, the market demand for WDG in the field of agriculture has been increasing.

The proportion of WDG in pesticide dosage form is also gradually increasing. With the deepening of research, researchers continue to develop high-performance additives, such as lignosulfonate dispersants, which can better balance the suspension stability and disintegration of WDG, solving some of the problems existing in the previous formulations and further improving the quality and performance of WDG.

Under the background of increasing global environmental protection awareness, the research and development and application of environmentally friendly additives will also become an important direction for the development of WDG in the future, in order to further reduce its impact on the environment. In order to meet the demand for efficient, low-toxicity and low-residue pesticides in agricultural production, the development of WDG products with high content and high active ingredients will be one of the future trends. In addition, the development of WDG with slow-release and controlled-release functions can extend the efficacy period of pesticides, reduce the number of applications, improve the utilization rate of pesticides, reduce the cost of agricultural production, and at the same time contribute to environmental protection.

In the future, the production process of WDG will be continuously optimized and innovated to improve the production efficiency and reduce the production cost. Jiangsu Longxin improves the production process of WDG granulation dryer for water dispersible granules, and the newly developed WDG granulation drying unit can greatly reduce the production cost of water dispersible granules and greatly improve the production efficiency. The application of advanced technologies and equipments such as high-efficiency granulation and new type fluidized bed drying realizes continuous and automatic production, reduces energy consumption and labor cost, and improves product quality and market competitiveness.

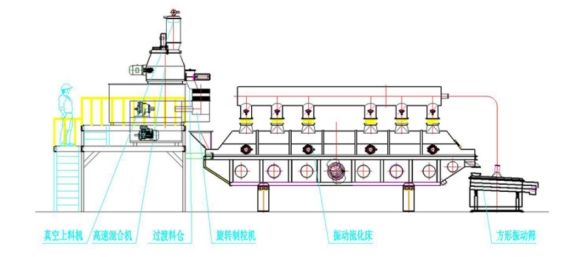

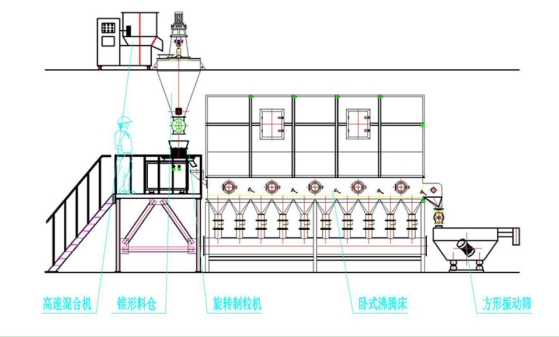

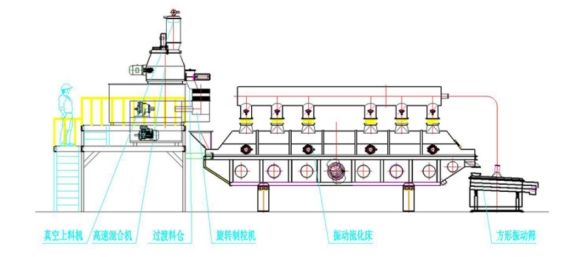

Water dispersible granule WDG granulation fluidized drying unit process flow

(1) Mixing of raw materials: add various raw materials of water dispersible granules, such as active ingredients, auxiliaries, fillers, etc., into the mixing equipment for full mixing according to a certain proportion of the formula, so as to make the components uniformly distributed and form a mixture with a certain fluidity.

(2) granulation: mixed materials through the granulation equipment made of uniform size particles. Common granulation methods include spray granulation, rotary granulation, boiling granulation and extrusion granulation, etc., of which extrusion granulation is one of the more commonly used methods. The granulated particles have a certain shape and strength, which is convenient for subsequent drying and processing.

(3) Feeding: the wet material after granulation is uniformly fed into the bed of the fluidized bed dryer through the feeding device. The feeding speed can usually be adjusted according to the production capacity and drying requirements to ensure that the material can be fully dried in the bed.

(4) Drying

Hot air supply: After the air is filtered by the air filter, it is sent into the heat exchanger by the blower to be heated, and the heated hot air enters into the bottom of the fluidized bed dryer through the air inlet pipe. The parameters of hot air temperature, air volume and air speed are finely que controlled according to the nature of materials, initial moisture content and drying requirements.

Fluidized drying: The hot air passes through the distribution plate at the bottom of the fluidized bed, forming a uniform airflow. When the airflow speed reaches the critical fluidization speed, the wet material particles on the bed plate are blown up and in the fluidization state, and fully contact with the hot air. In this process, the hot air will transfer heat to the material particles, so that the water inside the particles evaporates rapidly, forming water vapor. The water vapor flows upward with the hot air, passes through the material layer and is discharged from the top of the fluidized bed dryer.

Drying control: In the drying process, by adjusting the temperature of the hot air, air volume, air speed and the residence time of the material in the bed and other parameters, to ensure that the material can be uniformly dried to the specified moisture content. At the same time, monitor the key indicators in the drying process, such as material temperature, outlet air humidity, etc., in order to ensure the drying effect and product quality.

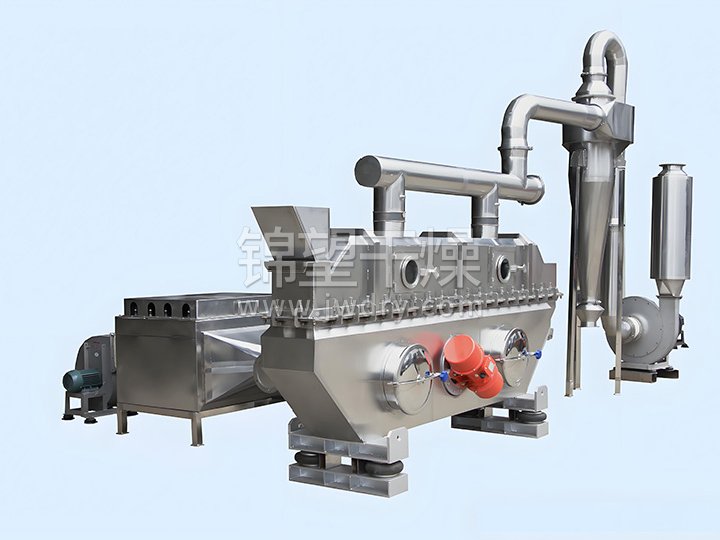

(5) Dust removal: the exhaust gas discharged from the top of the fluidized bed dryer contains a certain amount of dust and fine particles, in order to reduce environmental pollution and material loss, the exhaust gas needs to be treated with dust removal. Usually, cyclone separator and bag filter are combined to remove dust. Cyclone separator firstly separates and recycles most of the larger particles in the exhaust gas, and then the exhaust gas enters into the bag filter to further remove the fine dust particles, and the exhaust gas after dedusting meets the environmental emission standards and is discharged into the atmosphere.

(6) Discharge: The dried material is discharged from the discharge port of the fluidized bed dryer into the subsequent screening, packaging and other processes. When discharging, the dried particles can be sieved by vibrating screen and other equipment to remove the unqualified large particles or fine powder, and get the water dispersible granule products with uniform particle size and in line with the quality standard.

(7) Sieving and granulation: the dried material is sieved through vibrating screen to separate the particles that do not meet the requirements of particle size. Unqualified large particles can be crushed and returned to the granulation process, and the fine powder can be processed according to the specific conditions, such as re-granulation or as waste material. After sieving the qualified products into the packaging process.

(8) Packaging: the qualified water dispersible granules after sieving will be packaged according to the specified packaging specifications and requirements, usually using plastic bags, paper bags or plastic drums and other packaging containers for packaging, and affixed with product labels, indicating the product name, specifications, date of production, shelf-life and other information, in order to facilitate the storage, transportation and sales.

Pesticide water dispersible granule dryer process and production equipment

Production process 1: weighing and dosing → mixing (ZGH-type vertical high-speed mixer) → granulation (ZL-type rotary granulator) → drying (XF-type boiling dryer) → sieving (ZS, FS-type oscillating sieve) → loading (ZKS vacuum feeding machine) → packaging

Production process 2: weighing and dosing → mixing (ZGH-type vertical high-speed mixer) → granulation (ZL-type rotary granulator) → drying (ZLG-type vibration fluidized bed) → screening (ZS, FS-type oscillating sieve)

Water dispersible granule WDG granulation fluidization drying unit performance characteristics

(1)High drying efficiency

Strengthen heat and mass transfer: hot air and material particles in the fluidized state of full contact, greatly increasing the contact area between the two and the contact time, so that the heat can be quickly transferred to the material, the moisture can also be quickly migrated from the inside of the material to the surface and evaporation, thus significantly improving the drying rate.

Rapid removal of moisture: in the drying process, the material particles are uniformly surrounded by hot air, water evaporation power is large, can be in a shorter period of time to reduce the moisture in the material to the specified content, improve production efficiency.

(2) Good drying quality

Good drying uniformity: the material in the fluidized bed dryer is in fluidized state, and the particles are constantly mixed and collided with each other, which makes the material more uniformly heated and avoids local overheating or under-drying, which ensures that the moisture content of the dried product is uniform and consistent, and is conducive to improving the stability of the product's quality.

Good product integrity: in the fluidization drying process, the relative motion between the material particles and the airflow is more gentle, will not cause excessive friction and collision of particles, reducing the particle crushing and abrasion, can effectively maintain the integrity of the particle size and appearance of the quality of the product to reduce the content of the product fines, improve the qualification rate of the product.

(3)Precise temperature control

Segmented heating design: some advanced water dispersible granules WDG fluidized bed dryer adopts segmented heating, the pre-drying section adopts high pressure and low air volume fan, so that the wetter particles can be completely fluidized; the drying section adopts low-pressure and high-air volume fan, which takes away more water per unit of time, and dries uniformly; the cooling section adopts high-air volume fan, which can quickly take away the heat and reduce the temperature of the product to achieve the requirements of moisture control and also It is convenient for subsequent packaging process.

Real-time temperature monitoring and adjustment: Equipped with temperature sensors and other monitoring equipment, it can accurately measure the temperatures at different locations in the drying process in real time, such as inlet temperature, material temperature, outlet temperature, etc., and automatically adjust the flow of hot air, temperature and other parameters according to the set temperature value to ensure that the drying process takes place in the refined temperature range, preventing the product quality from being affected by the over- or under-temperature.

(4) Strong environmental performance

Less dust emission: the design focuses on sealing to reduce the leakage and flying of material dust in the drying process, and at the same time, it is equipped with effective dust removal equipment, such as cyclone separator and cloth bag duster, etc., which purify the discharged exhaust gas, so that the concentration of dust emission is far lower than the national environmental protection standard, which effectively protects the environment and the health of the operators.

Hot air recycling: some fluidized bed dryer adopts hot air recycling system, which recycles, filters and reheats the hot air after drying and then recycles it, which not only improves the energy utilization rate, reduces energy consumption and production cost, but also reduces the thermal pollution to the environment due to the emission of exhaust gas.

(5)Convenient operation and maintenance

Reasonable structural design: the upper and lower beds of the drying host adopt quick-opening structure, which changes the traditional structure of bolted connection and greatly facilitates thorough cleaning of the system. The interior of the lower bed body is made of stainless steel full welding to avoid sewage entering the insulation layer during cleaning, thus affecting the quality of the product, and there is also a cleaning port for easy cleaning of the equipment.

Optimization of spreading bed plate: the hole type of spreading bed plate adopts combined structure, the front section adopts tongue-shaped hole, so that the material can go forward smoothly without material leakage phenomenon; the middle and back end adopts straight hole, the hot air penetration rate is higher, and the heat exchange of drying process is more adequate.

(6) Wide range of application

Strong material adaptability: it is not only suitable for drying water-dispersible granules, but also can be widely used in drying, cooling, humidifying and other operations of powder, granule, flake and fiber materials in various industries such as chemical, pharmaceutical, food, feed, mineral, metallurgy and building materials, etc., which can meet the drying needs of different industries and different materials.

Diversified product specifications: according to the user's actual production needs, design and manufacture of equipment with different output scales, the output of a single production line of 100kg/h, 200kg/h, 300kg/h, 500kg/h, 800kg/h and so on can be selected, but also according to the special requirements of the customized production, in order to adapt to the different enterprises of the production scale and the needs of the development.

Tel

Tel E-mail

E-mail Address

Address