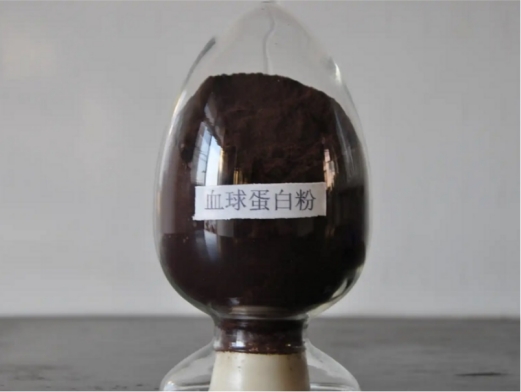

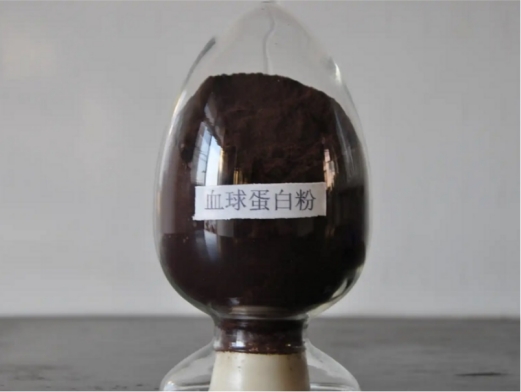

In slaughterhouses, pig blood needs to be collected by means of specialized collection devices, usually in clean stainless steel containers or piping systems, to ensure the purity of the blood and to avoid the mixing of impurities. The collection process should be as fast as possible to maintain the freshness of the blood, as fresh pig blood is of better quality and more conducive to subsequent processing. Through processes such as drying (e.g. spray drying or vacuum freeze drying) and pulverizing, pig blood is made into a powdered product. This pig blood protein powder can be used as a nutritional supplement and added to some functional foods for nutrients such as protein and iron.

With people's deepening understanding of the value of pig's blood resources, pig's blood deep-processing industry is gradually emerging, such as the production of pig's blood protein powder, plasma protein powder, hemoglobin powder, etc. as food additives or feed additives, etc., which will directly lead to the demand for pig's blood spray dryer. Changzhou Jinwang's spray dryer focuses on the application of energy-saving technology to reduce energy consumption and improve energy utilization through optimizing the drying process, improving the heating system and ventilating device and so on, in order to reduce the production cost of enterprises. We not only provide customized equipments, but also provide customers with personalized overall solutions, including process design, equipment selection and matching, operation training, after-sales service, etc., to help customers realize the optimization of the whole process from pig's blood collection to the production of dried products, to improve the production efficiency and product quality, and to enhance the market competitiveness of customers.

Slaughterhouse pig blood spray dryer equipment structure

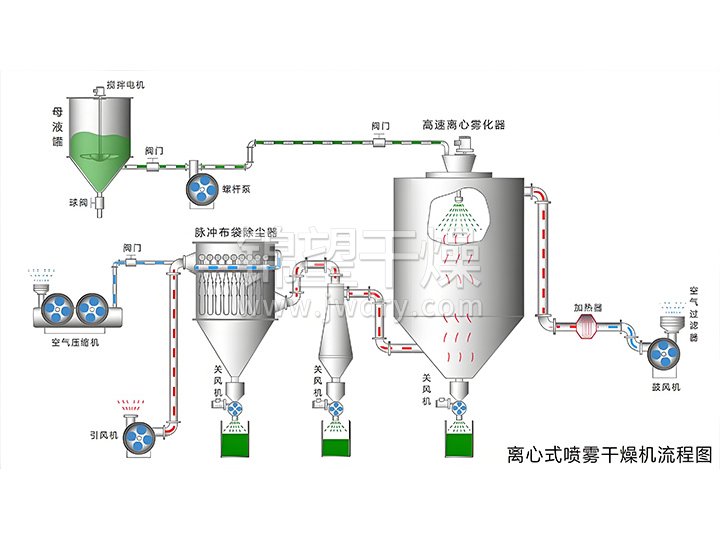

(1) Atomization system: this is one of the core parts of pig blood spray dryer. Centrifugal atomizer is to use the centrifugal force generated by the high-speed rotating disc to disperse the pig blood into tiny droplets, and its rotational speed can reach several dry revolutions per minute, which can make the pig blood evenly distributed in the drying chamber. The diameter of atomized pig's blood droplets is generally between tens of microns and hundreds of microns, which can greatly increase the contact area between pig's blood and hot air and speed up the drying speed.

(2) Drying room: it is the main place for drying pig blood droplets. The shape and size of the drying chamber according to the processing capacity of the equipment and design requirements, common tower-type drying chamber. The inner wall of the drying chamber is generally smooth to reduce the phenomenon of droplet sticking to the wall. Hot air enters from the bottom or side of the drying chamber, mixes fully with the atomized pig blood droplets and carries out heat exchange, so that the moisture in the droplets evaporates rapidly and forms solid pig blood powder.

(3) Hot air system: it mainly includes air filter, heater and fan. Air filter is used to remove impurities in the air, such as dust, hair, etc., to ensure that the air entering the drying room is clean. The heater usually adopts electric heating, steam heating or heat-conducting oil heating, etc., to heat the air to a suitable temperature, usually around 150~250℃, to provide heat for drying pig blood droplets. The fan is then responsible for conveying the heated air to the drying chamber and controlling the flow rate and flow of the air to ensure that the drying process is carried out smoothly.

(4) Collection system: it is used to collect the dried pig blood powder. It mainly includes cyclone separator and bag duster. The cyclone separator utilizes the principle of centrifugal force to separate most of the pig's blood powder from the airflow and fall into the collection container at the bottom. The cloth bag duster further captures the residual tiny pig blood powder particles to prevent them from entering the atmosphere and causing dust pollution, and also improves the recovery rate of the product.

(5) Control system: Modern pig blood spray dryer is equipped with an advanced control system, which can carry out fine que control of various parameters of the equipment. This includes the rotational speed of the atomizer (for centrifugal atomizer), the inlet air temperature, the outlet air temperature, the air volume of the fan, the flow rate of the pump and so on. These parameters are monitored in real time by sensors and the data are fed back to the control system, which automatically adjusts them according to the preset programs and parameters to ensure the stability of the drying process and the consistency of product quality.

Slaughterhouse pig blood spray dryer operation points and precautions

(1) Pre-treatment of pig blood: before spray drying, pig blood needs to be pre-treated properly. First of all, it should be filtered to remove the impurities in it, such as tissue fragments and blood clots. A strainer or filter can be used, and the pore size of the strainer is usually around 100~200μm. Then, pig blood can be anticoagulated as needed to prevent blood coagulation, and commonly used anticoagulants include sodium citrate, etc., and the concentration of its use is generally 0.3% to 0.8%. In addition, pig blood can also be concentrated to improve the drying efficiency.

(2) Inlet air temperature control: Inlet air temperature is one of the key factors affecting drying effect and product quality. Too high temperature may cause pig blood protein denaturation, affecting the nutritional value and solubility of the product; too low temperature will make the drying speed too slow, or even unable to complete the drying. Generally speaking, the temperature of inlet air can be controlled between 180~220℃, and at the same time, it should be adjusted appropriately according to the actual situation of flow and concentration of pig's blood.

(3) Outgoing air temperature monitoring: Outgoing air temperature is also an important parameter, which can reflect the degree of drying in the drying room. Usually the air outlet temperature should be controlled between 70~90° Celsius. If the air outlet temperature is too high, it means that there is excess heat in the drying chamber, which may cause excessive drying or scorching of pig's blood powder; if the air outlet temperature is too low, the drying may be incomplete, and the water content of the product is too high.

(4) Adjustment of atomizer: for centrifugal atomizer, pay attention to the adjustment of its rotational speed, too high rotational speed may lead to too small droplets, easily taken out of the drying chamber by the hot air, resulting in product loss; too low rotational speed, the droplets are too large, drying time is prolonged, affecting the drying efficiency.

(5) Equipment cleaning and maintenance: after use, the equipment should be cleaned in time to prevent pig's blood residue from scaling after drying, affecting the next use of the equipment. In particular, the atomizer, drying chamber, collection system and other parts of the equipment should be regularly and thoroughly cleaned. At the same time, the various parts of the equipment, such as fans, heaters, pumps, etc., should be checked regularly to ensure their normal operation, and the parts that are easy to wear and tear should be replaced regularly, such as filters and bags.

Slaughterhouse pig blood spray dryer performance advantages

(1)High drying efficiency

Rapid drying: spray dryer can atomize pig blood into very small droplets, so that its surface area is greatly increased, and when it comes into contact with hot air, the water can evaporate 95%~98% in an instant, and the drying time only takes a few seconds, which greatly improves the drying efficiency, and it can quickly transform pig blood into dry pig blood powder, which is suitable for large-scale production.

Continuous production: the equipment can continuously feed and discharge materials, realizing automatic continuous production, reducing the downtime in the production process, further improving the overall production efficiency, and able to meet the demand for processing large quantities of pig's blood in slaughterhouses.

(2) Good product quality

Retention of nutrients: Due to the fast drying speed, the nutrients in pig's blood such as protein, amino acid, etc. finish drying in a short time and are less affected by heat, which can zui maximize the retention of its original nutrients and biological activity, and improve the added value of the product.

High product uniformity: the atomized pig's blood droplets are uniform in size, evenly mixed and dried with hot air in the drying room, which makes the pig's blood powder particles obtained in the end of zuì uniform, with good fluidity, solubility and dispersion, stable product quality, and it is not easy to have problems such as caking in the process of storage and use.

(3)Simplified production process

Reduced processes: For pig's blood with wet content of 40%~60% (special materials up to 90%), spray dryer can dry it into powdered products at one time, and there is no need for subsequent processes such as crushing and screening after drying, which reduces the production links, not only saves the time and labor cost, but also reduces the impurities that may be introduced in the production process, and improves the purity of the products.

Easy to control: The operator can conveniently fine-que adjust and control the parameters such as inlet air temperature, outlet air temperature, atomizer rotation speed, feeding speed and so on through the control system, so as to flexibly adjust the drying process according to different production needs and product requirements, and ensure the consistency and stability of product quality.

(4)Hygiene and environmental protection

Conform to health standards: the whole set of spray system is easy to clean, in line with GMP requirements, the equipment is usually made of stainless steel, the surface of the part in contact with pig's blood is smooth, with no hygienic dead ends, which is easy to clean and disinfect, and it can effectively prevent bacterial growth and product contamination to ensure the hygienic quality of the product.

Good environmental performance: the spray dryer is equipped with efficient dust removal devices, such as cyclone separator and bag duster, which can effectively collect the pig blood powder particles generated during the drying process and prevent them from being discharged into the atmosphere to cause dust pollution, and at the same time improve the recovery rate of the product and reduce the waste of materials.

(5)Strong adaptability

Material adaptability: It is not only suitable for drying pig's blood, but also can be widely used in drying a variety of other liquid materials, such as milk, egg liquid, fruit juice, etc. in the food industry, and a variety of solutions, emulsions, suspensions, etc. in the chemical industry, which is of strong versatility and adaptability.

Heat-sensitive material processing: It is especially suitable for drying heat-sensitive materials, and can quickly complete the drying process at a lower temperature, avoiding the deterioration and denaturation of the materials due to prolonged heating, and can maintain the color, aroma, taste and nutrients of the materials, which broadens the scope of application of the equipment.

Tel

Tel E-mail

E-mail Address

Address