A savory flavor is a flavor used to enhance or impart a savory flavor to food. It is a complex mixture of various ingredients, the main purpose of which is to simulate and intensify the flavor of salty ingredients such as meat, seafood, vegetables, etc., so as to give the food a stronger and more authentic flavor during processing or cooking. With the continuous progress of the modern food industry, more and more processed foods are emerging, such as instant noodles, puffed food, canned food, etc. These foods need to be enhanced or simulated by adding savory flavors to enhance or simulate the various flavors loved by consumers, thus driving the growth of savory flavor market demand. Consumers nowadays have higher expectations for the taste and flavor of food, and want to enjoy a richer, more intense and realistic flavor experience. Savory flavors can meet this demand, whether in the casual food, convenience food or catering industry, have been widely used, which in turn led to increasing market demand.

Spray drying is one of the key links in the production process of savory flavors. Enterprises need spray dryers to convert liquid flavor raw materials into powder form to improve their stability, solubility and fluidity for easy storage, transportation and addition to various food products. Jinwang Drying continuously researches and develops new technologies and improves the structure of the equipment in order to meet the higher requirements of savory flavors and spices enterprises on the drying speed, heat utilization rate and other performance indexes of the spray dryer. Jinwang's spray dryer for spices can preserve the aroma and flavor components of the flavor to the maximum extent during the drying process, while avoiding the production of burnt taste or other off-flavors. The new equipment is equipped with precise temperature control, uniform spray effect and good material dispersion to ensure the stability of product quality. For different savory flavor products in the composition, viscosity, heat sensitivity and other aspects of the differences, the new spray dryer has a certain degree of flexibility and adaptability, according to the different characteristics of the material to adjust. With the market demand for personalized, differentiated products increased, we can also non-standard custom production of special specifications, special features of savory flavor spray dryer.

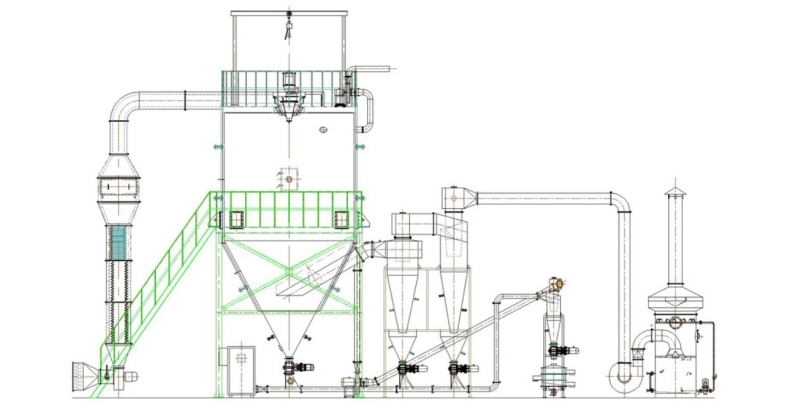

Savory flavors and spices spray dryer process flow

(1) Liquid preparation: The raw materials of savory flavors and seasonings to be dried are blended into liquid with certain concentration, viscosity and fluidity, and filtered to remove impurities and insoluble particles to prevent clogging of the atomizer.

(2) air filtration and heating: the air is first filtered through the primary, secondary and high efficiency filters to remove dust, microorganisms and other impurities, to meet the hygiene requirements of food production. The filtered air enters the heater and is heated by steam, electricity, fuel oil or gas to the set inlet air temperature, which is generally about 160℃~220℃.

(3) Material liquid atomization: The filtered and heated air enters the air distributor on the top of the dryer in a spiral shape uniformly. At the same time, the material liquid is transported to the centrifugal atomizer on the top of the dryer by the pump from the material liquid tank through the filter. In the centrifugal atomizer, the material liquid in the high-speed rotation of the centrifugal force, is thrown into a very small fog droplets, greatly increasing the surface area of the material liquid and hot air contact.

(4) Drying process: the atomized material liquid and hot air parallel flow contact, due to the large surface area of the droplets, the moisture in the hot air stream instantaneous evaporation. The hot air will transfer the heat to the material liquid droplets, so that the moisture in them is rapidly vaporized and taken away by the hot air, in a very short period of time (generally as long as 5~15 seconds) drying for the finished product.

(5) Finished product collection: part of the dried finished product is directly discharged from the bottom of the drying tower, and the other part enters the cyclone separator with the airflow. In the cyclone separator, the finished product and exhaust gas realize separation, and the finished product is collected into the powder collecting cylinder. In addition, in order to improve the recovery rate, it can also be equipped with a secondary dust removal device at the outlet of the fan, such as a bag filter.

(6) Exhaust gas discharge: the exhaust gas separated from the finished product is extracted by the fan, and then discharged into the atmosphere after the exhaust gas treatment device meets the standard to meet the environmental protection requirements. Tail gas treatment can be selected according to the actual situation, such as water film dust removal, wet electrostatic dust removal and so on.

(7) Cooling and packaging: The collected finished products may have high temperature and need to be cooled to prevent lumping and deterioration. Usually use cold air attached to the wall of the downstream system or pneumatic conveying system in the dehumidification, purification, temperature control air on the finished product cooling and conveying, and at the same time play a role in mixing, and then the cooled finished product will be transported to the clean collection of powder room for packaging to reduce the cross-pollution of materials.

Savory flavor seasoning spray dryer performance characteristics

(1)High drying efficiency

Fast drying: centrifugal spray dryer can dry the liquid raw material of savory flavor seasoning into powder in a very short time (usually a few seconds to a dozen seconds). This is because it atomizes the material liquid into very small droplets through the centrifugal atomizer, so that the contact area between the material liquid and the hot air is greatly increased. For example, the diameter of the atomized droplets can be as small as tens of microns, and such tiny droplets can make the water evaporate quickly under the action of hot air, which greatly improves the drying speed.

Continuous production: The equipment can realize continuous uninterrupted production process. As long as to ensure a stable supply of material and liquid and suitable drying conditions, can continue to produce dried savory flavor products. This is for large-scale production of savory flavors and condiments for enterprises, can effectively improve production efficiency, to meet the market demand for a large number of.

(2) Excellent product quality

Good particle uniformity: the centrifugal spray dryer produces savory flavor powder particles of uniform size. This is due to the high-speed rotation of the centrifugal atomizer so that the material liquid is uniformly dispersed into droplets, and under the same drying conditions, these droplets can be synchronized drying, resulting in the formation of a more uniform particle size of the product. Savory flavors with uniform particle size perform better in terms of solubility, fluidity, etc. For example, when added to food, they can be more evenly dispersed, which is conducive to ensuring the consistency of food flavor.

Effective retention of flavor and nutrients: In the drying process, due to the parallel flow drying mode, hot air and atomized material flow in the same direction, the moisture on the surface of the material evaporates quickly, so that the temperature inside the material particles will not be too high. This mild drying method can zui greatly reduce the savory flavor seasonings in the flavor components and nutrients in the destruction, to ensure the quality and taste of the product.

(3)High degree of automation

Easy operation: Centrifugal spray dryer is equipped with advanced automation control system. The operator can conveniently set and adjust the key parameters in the drying process through the control panel, such as inlet air temperature, outlet air temperature, atomizer rotation speed, feeding speed and so on. The equipment can run automatically according to the set parameters and monitor the operation status in real time, reducing the frequency of manual intervention and labor intensity.

Fault warning and automatic protection: the automation system also has fault warning and automatic protection functions. When there are abnormalities in the equipment, such as high temperature, abnormal pressure, motor overload, etc., the system will immediately issue an alarm and take corresponding protective measures, such as stopping feeding, stopping heating, etc., in order to prevent equipment damage and product quality accidents.

(4)Flexible

Adapt to a variety of material characteristics: for different viscosity, concentration and composition of savory flavor seasoning material, centrifugal spray dryer has a good adaptability. By adjusting the rotational speed of the atomizer, feed rate and drying parameters, etc., it can successfully dry a variety of types of liquids. For example, for liquids with high viscosity, the rotational speed of the atomizer and the temperature of the inlet air can be increased appropriately to ensure good

Atomization effect and drying efficiency.

Adjustable product specifications: According to the market demand and product requirements, the specifications of the savory flavor products such as particle size and powder density can be flexibly adjusted. By changing the structure and operating parameters of the atomizer, it can produce products with different particle size distributions to meet the requirements of different food processing techniques on the characteristics of savory flavor particles.

(5) Better environmental performance

Effective dust control: dust will be generated during the drying process, and the centrifugal spray dryer is equipped with a perfect dust collection system. These devices can efficiently separate the dried finished product from the exhaust gas with a high collection rate, effectively reducing the dust emission into the air, which not only reduces the loss of product, but also meets the requirements of environmental protection.

Convenient exhaust gas treatment: For the exhaust gas generated during the drying process, the equipment can be conveniently connected to the exhaust gas treatment device. Through the use of appropriate exhaust gas treatment technology, such as washing, adsorption, etc., the odor and harmful substances in the exhaust gas can be treated so as to meet the emission standards before discharge, reducing the pollution of the environment.

Tel

Tel E-mail

E-mail Address

Address